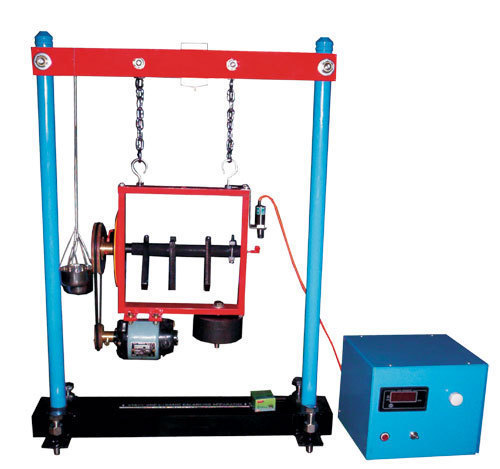

Motorised Governor Apparatus

Motorised Governor Apparatus Specification

- Frequency

- 50 Hz

- Core Components

- Governor Mechanism, Motor, Loading Arrangement, Digital Display

- Power Source

- Electric (AC Mains)

- Automation Grade

- Manual / Semi-Automatic

- Model No

- MGA-01

- Temperature Range

- Ambient to 50C

- Capacity

- 1 set

- Voltage

- 220 V AC

- Feature

- Motor Driven, Accurate Measurement, Stable Base, Comprehensive Instrumentation

- Measurement Range

- 0 - 3000 RPM

- Accuracy

- 1% for Speed Measurement

- Equipment Materials

- Mild Steel with Powder Coated Finish, Stainless Steel Parts

- Type

- Engineering Lab Training Apparatus

- Usage

- Demonstration and Study of Governors Characteristics

- Display Type

- Digital RPM Indicator

- Dimension (L*W*H)

- 750 x 500 x 600 mm

- Weight

- Approx 35 kg

About Motorised Governor Apparatus

Motorised Governor Apparatus

The unit of main spindle driven by a variable speed motor. Three different governor assemblies can be mounted over the spindle. Pointer measures the lift of the governor. Students can calculate characteristics of governor and compare their performance viz. Sensitiveness, stability, governor effort etc.

Specifications:

Governor assemblies, Hartnell, porter & propel governor assembly one each with rotating weights.

- Variable speed FHP D.C motor to drive the main spindle.

- Sliding weights for porter & proell governor

- Scale & a pointer to measure governor lift.

- Spring & Spring compression adjustment arrangement.

Versatile Governor Study

This apparatus allows investigation of multiple governor typesWatt, Porter, Proell, and Hartnellusing interchangeable assemblies. Students and professionals can explore the dynamic characteristics of both spring-loaded and gravity-loaded governors, gaining a thorough understanding of their operational principles and applications in engine speed regulation.

Precision Control and Measurement

Equipped with a speed regulator and digital RPM readout, the apparatus provides accurate speed measurement with an impressive 1% accuracy. Its magnetic pickup sensor ensures reliable, real-time speed monitoring across the 03000 RPM range, aiding in precise experimental analysis and data collection.

Safe and Durable Design

The apparatus features a powder-coated mild steel frame and stainless steel components, ensuring long-term durability. Essential safety elements such as overload protection and an emergency stop enhance operational safety, while the natural air-cooled system keeps the unit efficient and quiet, maintaining a noise level below 60 dB.

FAQs of Motorised Governor Apparatus:

Q: How does the speed control system work on this governor apparatus?

A: The speed on the Motorised Governor Apparatus can be varied manually through a built-in regulator. The digital indicator provides real-time RPM readings, enabling precise adjustments during experiments and demonstrations.Q: What are the main benefits of using interchangeable governors in this apparatus?

A: Interchangeable governor types (Watt, Porter, Proell, Hartnell) allow users to compare different mechanical principles and characteristics within a single setup, making the apparatus ideal for comprehensive learning and research in engineering laboratories.Q: When is it necessary to use the emergency stop feature?

A: The emergency stop should be employed whenever immediate cessation of operation is required, particularly in cases of abnormal noise, excessive vibration, or when an unsafe condition is observed, to protect both the user and equipment.Q: Where is this apparatus typically used?

A: The apparatus is mainly used in engineering educational institutions, research laboratories, and technical training centers throughout India for demonstrating and studying governor operation and speed control principles.Q: What process is followed for conducting a governor characteristic experiment?

A: Users select the desired governor, load it on the apparatus, and gradually increase speed using the regulator. Observations on governor movement and RPM readings are recorded to analyze characteristics such as stability, sensitivity, and speed regulation behavior.Q: How is noise managed during apparatus operation?

A: The apparatus uses a natural air cooling system and a precision-coupled drive to minimize operational noise, keeping levels below 60 dB for a safer and quieter laboratory environment.Q: What usage advantages does the digital RPM indicator offer?

A: The digital RPM indicator provides accurate, real-time feedback of governor speed, improving experiment reliability, simplifying data collection, and aiding in the demonstration of governor performance characteristics with high clarity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Theory Of Machine Lab Category

Coriolis Component Of Acceleration

Price 48000 INR

Minimum Order Quantity : 01 Piece

Dimension (L*W*H) : Approx. 350 mm x 250 mm x 250 mm

Usage : Educational, Laboratory Experimentation

Measurement Range : Demonstrative, Subject to Water Jet & Disc RPM

Accuracy : Designed for Educational Use (Demonstrative Accuracy)

Epicyclic Gear Train Holding Torque Apparatus

Price 48000 INR

Minimum Order Quantity : 01 Piece

Dimension (L*W*H) : 600 mm x 400 mm x 350 mm

Usage : Educational, Demonstration of Epicyclic Gear Train Principles

Measurement Range : 0 0.5 Nm

Accuracy : 2%

Static And Dynamic Balancing Apparatus

Price 21600 INR

Minimum Order Quantity : 01 Carton

Dimension (L*W*H) : 900 x 450 x 600 mm

Usage : Laboratory, Educational, Research

Measurement Range : Up to 100 mm eccentricity

Accuracy : 0.05 g

Motorised Gyroscope Apparatus

Price 24000 INR

Minimum Order Quantity : 01 Carton

Dimension (L*W*H) : 600 x 400 x 500 mm (Approx)

Usage : Educational, Demonstration of Gyroscopic Effect

Measurement Range : 04000 RPM

Accuracy : 1%

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry