Call: 07971550048

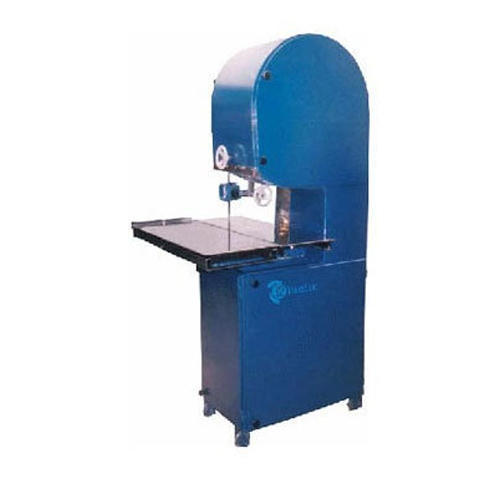

Bone Cutting Machine

Price 84000 INR/ Piece

MOQ : 1 Piece

Bone Cutting Machine Specification

- Temperature Range

- Ambient to 60C

- Capacity

- 100-300 kg/hr

- Voltage

- 220V/380V

- Model No

- BCM-100

- Automation Grade

- Semi-Automatic

- Core Components

- Motor, Blade, Frame

- Power Source

- Electric

- Measurement Range

- Up to 300 mm

- Accuracy

- 1 mm

- Feature

- Rust proof, Easy cleaning, Heavy Duty Operation, Safety lock

- Frequency

- 50 Hz

- Equipment Materials

- High-grade Stainless Steel

- Type

- Table top bone cutting machine

- Usage

- Bone and Meat Cutting

- Display Type

- Analog

- Dimension (L*W*H)

- 1000 mm x 700 mm x 1600 mm

- Weight

- Approx. 120 Kg

Bone Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Western Europe, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2015

About Bone Cutting Machine

Details:- Our Bone and Meat cutting machine is considered to be unique in the market because of Fitted with large moving table made from stainless steelExtension table operated on four ball-bearing rollers

- Special heavy axles for easy and firm movement

- Power consumption

- Fitted with premium blade, starter, cord and plug

Widely Used In:

- Meat packing

- Wholesale fish industry

Precision and Safety Combined

With a blade crafted from stainless steel alloy and surface finished to a polished sheen, the BCM-100 guarantees accuracy, hygiene, and long-lasting performance. The emergency stop, blade guard, and safety lock collectively ensure a safe working environment, making it suitable even for high-volume use in commercial meat processing settings.

Robust Construction and Easy Maintenance

Engineered from high-grade stainless steel, the machine resists rust and withstands continuous-duty operation. The floor-mounted design and polished surfaces allow for quick cleaning, while the heavy-duty frame assures stability during operation, handling bone and meat cutting tasks efficiently day after day.

Versatile Applications and User-Friendly Operation

Suitable for slaughterhouses, butcher shops, and meat processing units, this bone cutting machine is equipped with a manual knob for adjusting cutting thickness and an analog display for real-time monitoring. Its semi-automatic operation and ergonomic build ensure ease of use and precise results every time.

FAQ's of Bone Cutting Machine:

Q: How does the BCM-100 ensure safe operation during bone and meat cutting?

A: The BCM-100 is equipped with multiple safety features including an emergency stop button, a protective blade guard, and a safety lock. These components help prevent accidental contact with the blade and allow for immediate machine shutdown if needed, enhancing operator safety.Q: What materials and design features contribute to the machine's durability and rust resistance?

A: Crafted from high-grade stainless steel with a polished finish, the BCM-100 resists corrosion and is easy to clean. This rugged construction ensures longevity, even in demanding environments typical of slaughterhouses and meat processing units.Q: When should operators manually adjust the cutting thickness, and how precise is this adjustment?

A: Operators can use the manual knob to adjust the cutting thickness based on the specific requirements of each cut, achieving a precision of 1 mm. Adjustments should be made whenever there's a need to process different types of meat or bone sizes for optimal results.Q: Where is the BCM-100 typically installed, and what are the requirements for setup?

A: The machine is designed for floor mounting and is commonly installed in slaughterhouses, butcher shops, and meat processing facilities. With dimensions of 1000 mm x 700 mm x 1600 mm and weighing approximately 120 kg, a stable and spacious location with access to a 220V or 380V power supply is recommended.Q: What is the process for cleaning and maintaining the bone cutting machine?

A: After operation, the polished stainless steel surfaces can be quickly wiped down and sanitized. Regular maintenance involves inspecting the blade, frame, and motor, ensuring that the safety mechanisms are functional, and periodically checking the analog display and cutting thickness adjustment knob for accuracy.Q: How does continuous-duty operation benefit meat processing businesses?

A: Continuous-duty operation enables the BCM-100 to process up to 300 kg of bone and meat per hour without interruption, improving workflow efficiency and reducing downtime in high-demand settings such as commercial slaughterhouses and export facilities.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry