Compression Testing Machine 200 Ton

Compression Testing Machine 200 Ton Specification

- Measuring Range

- 0 - 2000 kN

- Specimen Size

- Up to 150 mm cubes or cylinders of 150 mm diameter x 300 mm height

- Mounting Type

- Bench/Stand Mounted

- Features

- Overload protection, sturdy construction, calibration certificate

- Accuracy

- 1% of reading

- Hardness

- High-strength platen surface, HRC > 60

- Operating Voltage

- 220V/440V AC

- Display Type

- Digital / Analog

- Max Height

- 600 mm (with platens)

- Power Supply

- 220V/440V AC, 50 Hz

- Response Time

- <1 second

- Frequency

- 50 Hz

- Humidity

- Up to 85% RH, non-condensing

- Automation Grade

- Semi-Automatic / Automatic

- Temperature

- 10C to 40C

- Interface Type

- RS232 / USB (Optional)

- Equipment Type

- Compression Testing Machine

- Port Size

- Standard

- Number of Specimens

- 1 per test

- Resolution

- 0.1 kN

- Test Range

- 0 - 200 Ton

- Application

- Concrete, cement, and building material compressive strength testing

- Usage

- Industrial / Laboratory

- Capacity

- 200 Ton

- Machine Weight

- Approx. 1100 kg

- Test Speed

- 0.1 to 5 mm/min (adjustable)

- Test Width

- 200 mm

- Test Stroke

- Max. 80 mm

- Control Mode

- Manual / Electric (Motorized)

Compression Testing Machine 200 Ton Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cash Advance (CA), Letter of Credit (L/C), Telegraphic Transfer (T/T)

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2015

About Compression Testing Machine 200 Ton

Compression Testing Machine 200 Ton

Features:

- Channel type model

- Complete with single pressure gauge & self made motor

- 440 load frames: available in 100 tons, 150 tons, 200 tons.

- Models available: hand operated & electric cum hand operated.

High-Performance Hydraulic System

This compression testing machine is equipped with a robust hydraulic pump, which can be operated manually or electrically for flexible use across different environments. The oil reservoir holds up to 10 litres to support smooth and efficient testing cycles for specimens up to 150 mm in size.

Advanced Safety and Calibration Features

An overload protection valve safeguards both operators and equipment during high-pressure testing. The machines calibration is traceable to national or international standards, which ensures precise and consistent measurement every time. Calibration certificates are provided for compliance and quality assurance.

Designed for Versatility and Reliability

With a fully adjustable test speed (0.15 mm/min) and a measuring range up to 2000 kN, this machine accommodates a variety of sample shapes, including cubes and cylinders. The digital or analog display gives clear readings, while the rugged frame withstands industrial wear and supports up to 1,100 kg of weight.

FAQs of Compression Testing Machine 200 Ton:

Q: How does the Compression Testing Machine ensure testing accuracy?

A: The machine delivers accuracy within 1% of reading, and all measurements are traceable to national or international calibration standards. A calibration certificate is supplied to guarantee consistent, reliable results.Q: What types of specimens can be tested with this machine?

A: This compression testing machine can accommodate specimens of up to 150 mm cubes or cylinders measuring 150 mm in diameter by 300 mm in height, making it suitable for concrete, cement, and various building materials.Q: When should I use manual versus electric operation?

A: Manual operation is ideal for sites lacking reliable power or when careful control is needed for sensitive specimens. Electric (motorized) control offers speed and convenience for routine or high-volume testing in laboratories and industrial settings.Q: Where should this machine be installed for optimal performance?

A: Install the machine on a stable bench or stand within a laboratory or industrial environment that maintains temperatures between 10C and 40C and relative humidity up to 85% (non-condensing) to ensure operational stability and safety.Q: What is the process for performing a compression test using this machine?

A: Place the specimen between the platens, adjust the settings for the appropriate test speed and control mode, then initiate the test using the manual lever or electric controls. Force is gradually applied until the specimen fails, and results are displayed digitally or via analog gauge.Q: What are the key benefits of using this compression testing machine?

A: Major benefits include high accuracy, rapid response time, robust overload protection, traceable calibration, ergonomic controls, sturdy construction, flexible operation modes, and compatibility with multiple display and interface options for efficient workflow integration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Engineering Equipment Category

Prismatic Compass With Stand

Price 1600 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Angular measurement, field orientation

Application : Land Survey, Engineering Survey, Geological Mapping

Specimen Size : Standard field use

Mounting Type : Tripod Stand

Core Drilling Machine

Minimum Order Quantity : 3 Pieces

Usage : Industrial and construction purposes

Application : Core drilling in concrete and masonry

Specimen Size : Drilling range based on bit and machine configuration

Mounting Type : Mobile with optional mounting

Thin Film Oven

Usage : Evaluating the aging properties of thin films

Application : Testing thin film properties

Specimen Size : Standard size as per ASTM D2872

Mounting Type : Floormounted

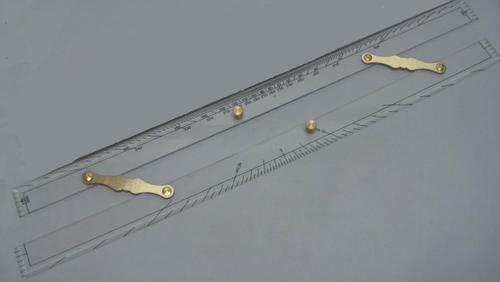

12inch Brass Parallel Rulers

Price 750 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industry and Laboratory

Application : For Civil Work

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry